Since 1998, the two companies have accumulated strong skills in the design and manufacture of complex systems combining on-board electronics (RF, motor control, low consumption), mechanics (fluidics, regulation, manufacturing processes, controls) and software (real time, communicating devices).

feasibility

Creative takes charge of your project as it is and intelligently carries it out in consultation with you

The technical, functional, budgetary and planning compromises are established by mutual agreement through a feasibility phase. We share with you our past experiences in terms of risks and opportunities, in order to secure your project and ensure optimal performance.

Development

Electronics, software and mechanical teams work together to find the most efficient and rational solutions to carry out your functions.

The ergonomics of the product, its style, the legibility and reactivity of the screens, the power consumption, the lifespan… are all parameters taken into account by our experts.

Industrialization and quality

At Creative, the factory is never far away and our designers think industrialization from the first stroke of the pen

It is a question of choosing technologies and materials adapted to the expected volumes and objective prices; we choose standard parts, reliable and reproducible processes and provide effective testing facilities.

electronics

• System specification and electronic architecture

• Analog and digital circuit design and simulation

• Battery powered electronics and software

• Programmable logic design (CPLD, FPGA)

• Microprocessor & microcontroller design

• Circuit board design, linked to test and manufacturing

• PCB design

• By wire communication (Ethernet, bus de terrain, CAN, CanOpen, Modbus …)

• DC motors, steppers and brushless control,

• Piezzoelectric control

• Wireless connectivity (Wifi, BlueTooth, Zigbee, LoRa) for IOT and M2M

• Custom wireless protocols (50K to 4 GHz)

software

• Embedded software

• Real time constraints

• Safety features

• With/without operating system

• Mobile and computer application development (Linux, Android …)

• Third party library integration

• Communication stacks

• Embedded medical device software development (IEC62304 medical class)

• ATM software according to DO-278B and ED-109

mechanics

• Proof-of-concept development and prototyping

• Mechanism development and optimisation

• Knowledge of medical-grade materials and manufacturing processes

• Rapid prototyping

• Computational simulation (FEA, CFD)

• Optimized integrated mechatronic system

• Design for manufacture and assembly, either for small quantities to large scale production

product design

and development

• Requirements definition and management

• Integrating multiple technologies and sub-systems

• Design of fail-safe architectures, risk analysis

• Closed-loop control systems

• Micro-fluidics

• Thermal management

• Sensors, actuators and optics

• Human interfaces

• Design of complete devices and their medical disposables

• Support for medical devices regulation, normative testing

• Design verification and validation

project methods

and management

• Formal, iterative or agile development cycle

• Design thinking, creativity workshop

• value added analysis / design to cost studies

• Product design support service : functional analysis, value analysis, risque analysis

expertise for after-sale

and maintenance

• Electronic, wireless, embedded software expertise

• Expertise on standards

• Technical and methodological training

• Maintain electronic systems in operational conditions

• System redesign, obsolescence management

ELEctronic manufacturing

Crossway's specialist teams supply, manufacture and test electronic boards fitted with SMD or through-hole components in small or medium production runs.

The expertise accumulated on a wide range of projects and Creative’s proximity enables the production unit Crossway to deal with any contingencies as quickly as possible. Obsolescence management or the search for replacement solutions can be implemented.

assembly

Crossway is not only a production unit for electronic sub-assemblies

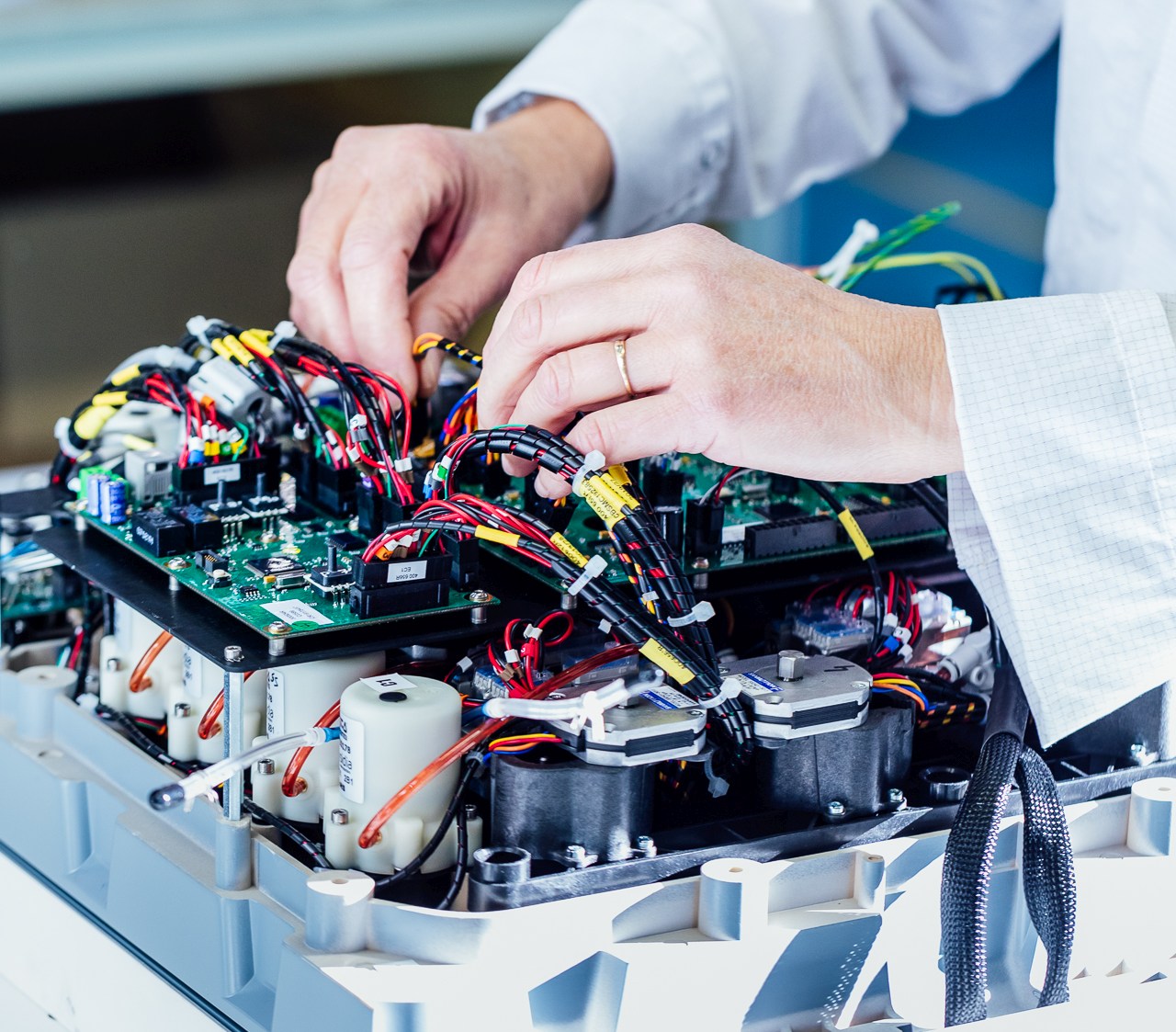

The serial integration of complete systems, combining electronic, mechanical, fluidic, modularized and tested separately, is a specialty of Crossway.

Services

Crossway provides procurement of electronic and mechanical components and obsolescence management...

…as well as service and operational maintenance of complete systems to support your product throughout its entire lifecycle.

services around

industrialization

• Total management of the industrialization project

• Taking into account economic and normative constraints within your deadlines

• Possibility of annualized contracts for purchases

• Guarantee of perfect reproducibility

• Accompaniment of the client throughout its development

complex systems

manufacturing

• Our know-how: federating and integrating different technologies!

• Complex mechatronic assembly:

– electronics,

– wiring,

– assembly of mechanical systems (motorization…),

– pneumatic and fluidic systems,

• Dedicated assembly line according to production volumes

• On-line testing of sub-assemblies and the complete product

production

methods

• Purchasing department and CAM software from order reception to invoicing

• DEK Horizon 265 Solder Paste Machine

• MYDATA MY15 SMD Component Soldering Machine

• Reflow oven Pyramax 98A compatible with leaded and lead-free process (RoHS)

• Double wave POWERFLOW ERSA with leaded and lead-free bath (RoHS)

• MIRTEC MV-3L Automatic Optical Inspection Machine (AOI)

• Stations for manual insertion, preforming, retouching, integration, wire-wiring

• Flexible test benches (RF, analog, digital), autonomous and automated

• Ovens and climatic chambers

• Cable cutting machine

• Specific wiring department (wire, wrapping, welding or crimping)

custom test benches

design

• test bench study

• Schematics of electronic test boards

• Realization of the test bench

• Automated test software development

• Inspection of measuring instruments

• Report creation

electronic board

production

• Traditional and SMD technology (in small and medium series)

• Integration of electronic assemblies, wired assemblies, functional tests

• Just-in-time production (Kanban, delayed differentiation,…)

• Obsolescence and Service Management

maintenance and

after sale

• Operational Maintenance

• Realization of the MCO plan

• Obsolescence watch

• Stockpiling of strategic components

• Preventive maintenance

• Guaranteed response times